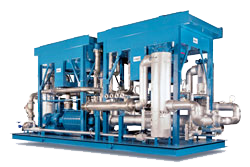

Landfill Gas Compression System

In today’s economy, there is an increasing demand for new sources of clean and cost-efficient energy. One of these sources is through capturing and utilizing gas from landfil ls.

What is Landfill Gas?

Landfill gas (LFG) is a consequence of decomposition. It’s typically composed of approximately 55% methane, 45% carbon dioxide, and <1% non-methane organic compounds (NMOCs).

Why is Landfill Gas Significant?

Since 2006, landfills have been the 2nd biggest manmade source of methane gas, accounting for more than 22% of the total. As a result, U.S. landfill operators are now required by the EPA to collect LFG through gas gathering systems. To remain in compliance, many landfill operators simply flare or burn LFG after they've gathered it.

However, even at 50% purity, the methane component of LFG is a valuable source of alternative energy for power generation. Consider the facts:

• In its raw form, LFG can power natural gas-burning, engine-driven & turbine generator packages.

• LFG is currently being used in some areas as a supplemental fuel for processes such as cement kilns and boilers.

• When the supply is sufficient and conditions are right, LFG is being used as a viable source of

fuel for combustion engine generators, micro turbines, and gas turbines to generate electricity.

How Can You Tap into the Power of LFG?

DeltaPro has the answer. We specialize in producing custom-made gas compressor and booster packages for use in the landfill, power generation, water, and petrochemical industries. We can fabricate a sliding vane, rotary screw, centrifugul, or reciprocating compressor solution customized especially for your needs, meeting even the most sophisticated specifications. In addition, our compressors offer an alternative to flaring and can help to boost your fuel gas or other energy sources.

Compressor Features

- Compresses, cleans, and delivers a volume of LFG at a specified pressure and quality.

- Operates at the lowest horsepower possible, maximizing efficiency while minimizing cost.

- Can be installed either indoors or outdoors.

- Ranges from a low pressure, single stage unit to a medium pressure, two- or three- stage system.

Contact Today

deltaproinc1@gmail.com

|

||||||